INDUSTRIAL VALVE DESIGNER AND MANUFACTURER

OXO Valve has over ten years of experience designing and manufacturing high-performance industrial valves. At OXO Valve, we expend continuous efforts to refine our products so that our industrial valves perform to the highest industry standards, both in terms of quality and safety.

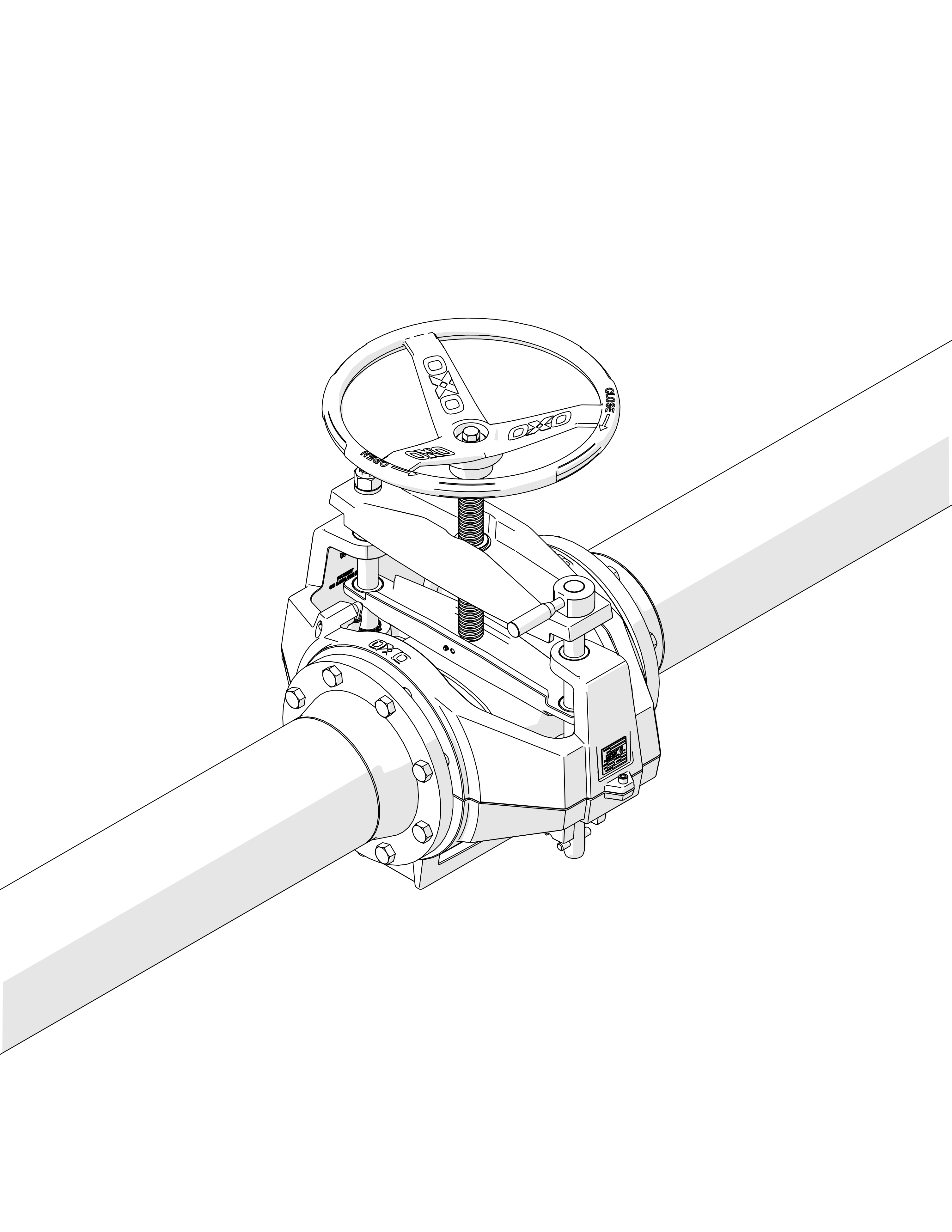

All OXO valves are available in full range of sizes and all types of actuators can be fitted : pneumatic, electric, handwheel, gearbox or hydraulic. When the valve is open, the sleeve offers a full-bore to media and is 100% drip tight when the valve is fully closed.

INNOVATION MOTIVATES OUR DEVELOPMENT

At OXO Valve, we are constantly in pursuit of innovation in an effort to produce industrial valves that make maintenance operations simple, productive, and safe. All maintenance is now achievable while leaving the entire valve on piping system. Thanks to this innovation, the maintenance of all types of industrial valves is revolutionized, leading to significant productivity and safety improvements.

Target industries

OXO valves are designed for highly resistant to abrasive/ corrosion slurries, powders, granular substances and more. Made with versatile materials, our products can withstand extreme conditions in any industrial process.

OXO valves ARE AVAILABLE IN many COUNTRIES

Find your nearest OXO distributor, or contact one of our technical experts to learn more about our products.

Unique and robust design

Low maintenance costs

Uncompromisingly light and solid

Exceed the highest durability standards across the industry